Product Line

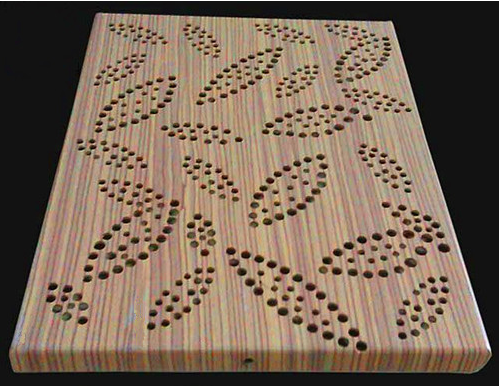

Tips for Selecting Carved and Perforated Aluminum Composite Panels

Prefabricated Integrated Seismic Support and Hanger System Solutions

- Product Description

-

1. Standardized Production:

-

- Commodity name: Tips for Selecting Carved and Perforated Aluminum Composite Panels

- Commodity ID: 1128741195946283008

Tips for Selecting Perforated Aluminum PanelsWhen selecting the thickness of aluminum panels, it's essential not only to consider the cost budget but also to ensure that the chosen thickness meets the specific production requirements. For standard-sized, flat panels with conventional dimensions, materials around 1.5mm or 2.0mm thick can typically be used for processing. However, if more complex shapes are involved, the thickness should be selected based on the specific design needs.1. Should punching be performed? For aluminum single panels, it is generally not recommended to use excessively thin aluminum sheets for punching, as this can easily lead to uneven hole edges during the punching process. Additionally, when punching small or micro-holes, it is also advisable not to use overly thick aluminum sheets, since thicker sheets require larger hole diameters. If the hole diameter is too small, there is a higher risk of needle breakage during punching. Therefore, we recommend using 2.0 mm, 2.5 mm, or 3.0 mm thicknesses as more suitable options.2. Is it considered extra-wide? Generally, panels exceeding 1.5 meters in width are classified as extra-wide. Extra-wide aluminum composite panels have wider surfaces and typically require the use of relatively thicker aluminum substrates for processing. This ensures a smoother panel surface. We recommend using materials with thicknesses of 2.5 mm or 3.0 mm.3. Is it excessively long? Typically, the maximum length for spray coating does not exceed 6 meters. However, for aluminum composite panels, it is recommended to keep the length within 4 meters. Panels longer than 4 meters are prone to warping and may become too bulky, resulting in heavier weight that increases the risk of damage or dents during transportation. For extra-long aluminum composite panels, we recommend using materials with a thickness of 2.5 mm or 3.0 mm.4. Is it curved? Curved aluminum single panels require welding during production. If the aluminum sheet is too thin, it may easily burn through during welding. For achieving a curved effect, we recommend using an aluminum single panel substrate with a thickness of 2.0 mm or greater for processing.

5. Are there any special shapes? If the design involves complex or intricate shapes that require multiple bending operations, it’s not advisable to use aluminum sheets that are too thick for processing. Typically, 2.0 mm or 2.5 mm would be the ideal choice. When selecting perforated aluminum single panels, please note the following:Punching aluminum panels demand higher standards than ordinary materials. Without sufficient expertise and capabilities, manufacturers cannot properly handle the production of aluminum panels—otherwise, issues such as incorrect dimensions, inconsistent color with noticeable variations, or uneven installation problems are likely to arise.1. Are there reinforcing ribs on the back of the aluminum panel? Reinforcing ribs can enhance the hardness of the aluminum panel to a certain extent, ensuring the panel remains flat.2. Is the surface of the aluminum panel properly polished and smooth? The quality of polishing directly affects the aesthetic appeal of the aluminum panel. If the polishing is insufficient, it may result in an uneven paint film after spraying.3. Are the edge-bending dimensions of the aluminum panels accurate? Any inaccuracies in the cutting dimensions or edge-bending sizes—especially deviations exceeding 2 mm—can affect the installation results, leading to situations where installation becomes impossible or the finished surface ends up uneven.4. Is the surface color treatment of aluminum panels well executed? Surface finishing not only protects the service life of aluminum panels but also directly impacts their aesthetic appeal. Some colors are unevenly sprayed, resulting in localized color variations. For aluminum panels featuring special patterns, engraving machines or automated CNC punching machines can be used for precise carving. Engraved and perforated aluminum panels allow for custom designs and versatile style combinations.

When selecting perforated aluminum single panels, please note the following:Punching aluminum panels demand higher standards than ordinary materials. Without sufficient expertise and capabilities, manufacturers cannot properly handle the production of aluminum panels—otherwise, issues such as incorrect dimensions, inconsistent color with noticeable variations, or uneven installation problems are likely to arise.1. Are there reinforcing ribs on the back of the aluminum panel? Reinforcing ribs can enhance the hardness of the aluminum panel to a certain extent, ensuring the panel remains flat.2. Is the surface of the aluminum panel properly polished and smooth? The quality of polishing directly affects the aesthetic appeal of the aluminum panel. If the polishing is insufficient, it may result in an uneven paint film after spraying.3. Are the edge-bending dimensions of the aluminum panels accurate? Any inaccuracies in the cutting dimensions or edge-bending sizes—especially deviations exceeding 2 mm—can affect the installation results, leading to situations where installation becomes impossible or the finished surface ends up uneven.4. Is the surface color treatment of aluminum panels well executed? Surface finishing not only protects the service life of aluminum panels but also directly impacts their aesthetic appeal. Some colors are unevenly sprayed, resulting in localized color variations. For aluminum panels featuring special patterns, engraving machines or automated CNC punching machines can be used for precise carving. Engraved and perforated aluminum panels allow for custom designs and versatile style combinations. By varying the size and irregularly distributing the perforations, you can create any desired shape—stylish, harmonious, and innovative. Recommended as a 2016 blockbuster hit!Key words:

By varying the size and irregularly distributing the perforations, you can create any desired shape—stylish, harmonious, and innovative. Recommended as a 2016 blockbuster hit!Key words:- When selecting

- consider whether the single board or aluminum plate is flat and suitable for punching. It is recommended to proceed with processing before making your final choice.

Utilizes standardized design and production processes to ensure consistent and stable product quality.

2. Easy Installation:

The prefabricated structure significantly simplifies on-site installation, saving time and labor costs.

Typically, installation can be completed with simple assembly and connection operations, such as bolt connections.

3. High Flexibility:

Can be flexibly adjusted and combined according to different pipeline layouts and installation environments.

4. Excellent Load-Bearing Capacity:

Meticulously designed and constructed with carefully selected materials, it possesses outstanding load-bearing capacity, effectively supporting the weight of pipelines and equipment.

Even under heavy loads, the structure maintains stability and safety.

5. Strong Corrosion Resistance:

Manufactured with corrosion-resistant materials or subjected to special surface treatments, extending its service life.

6. Easy Maintenance and Inspection:

The structural design facilitates later maintenance and inspection, allowing for convenient checking and repair of pipelines and equipment.

7. Aesthetic and Neat Appearance:

Features a simple and elegant design that harmonizes with the building environment, enhancing overall aesthetics.

关键词: Tips for Selecting Carved and Perforated Aluminum Composite Panels

Leave a Message Online

If you're interested in our products, please leave us your email, and we'll reach out to you as soon as possible. Thank you!

Related Products